Unlocking the Potential of Automated Grain Grading with Our Models and Calibrations

In the world of agriculture, precision is key—especially when it comes to grain grading. We are introducing a cutting-edge approach combining Machine Learning models, Machine Vision hardware, and Near-Infrared Spectroscopy calibrations. These technologies are not just improving grain grading; together they're transforming it, making the process faster, more accurate, and incredibly consistent from farm to destination. Let’s dive in!

Decoding Machine Learning

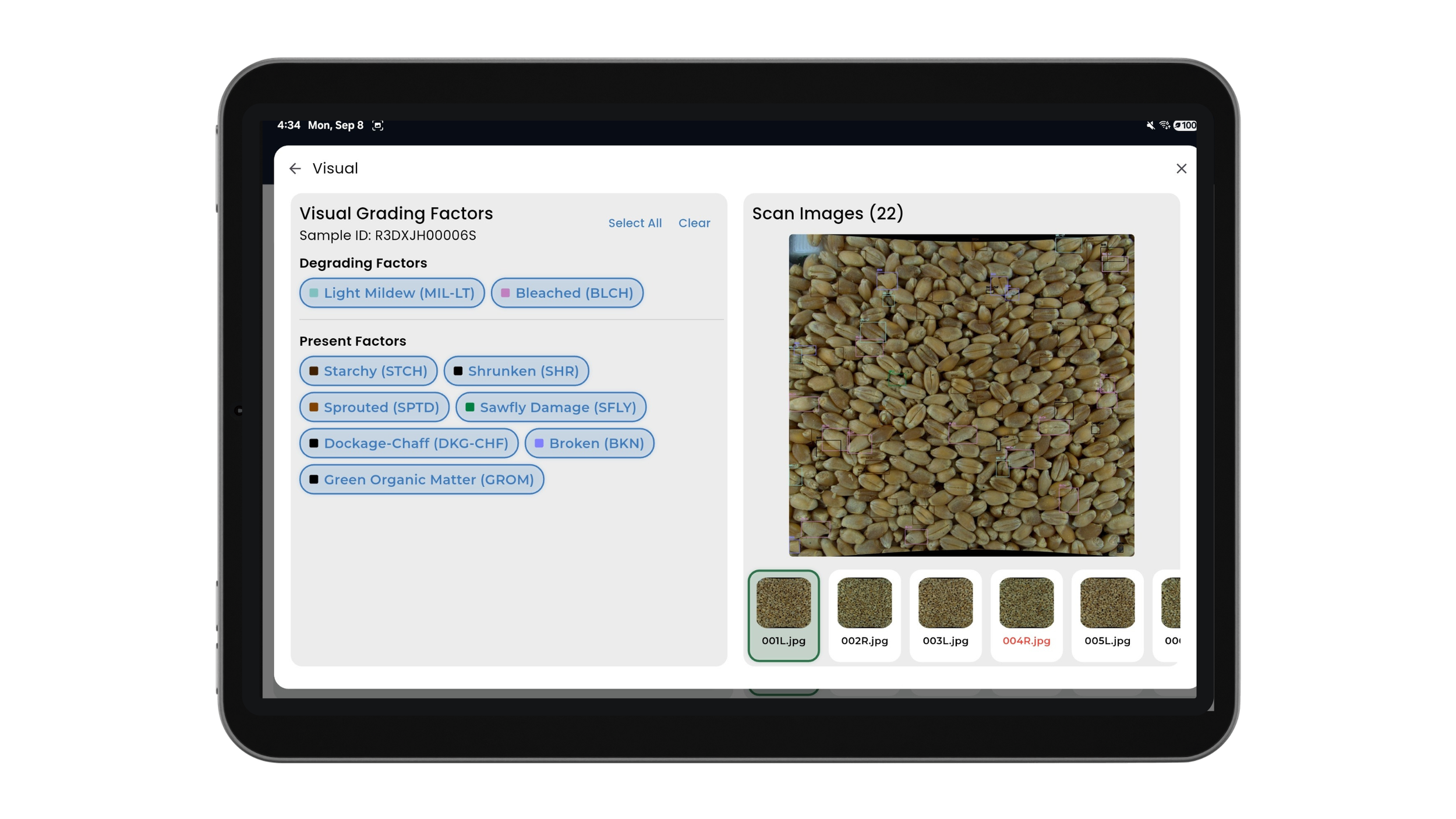

Imagine teaching a computer to recognize a cat or a dog through numerous photos. Machine Learning in grain grading works similarly. By analyzing countless images of grains, we train our software to identify grain grading factors such as diseases, damages, foreign materials to address complex assessments such as degree of soundness and HVK. This automated expertise ensures that grain grading is not only quick but exceptionally reliable.

The Eyes of the Machine: Machine Vision

Machine Vision gives our hardware the "sight" required to inspect grains. Like human eyes translating a view into data for the brain, Machine Vision captures images of grains and translates these into data points that Machine Learning uses to evaluate quality. This process ensures that each grain is assessed with unparalleled precision.

Peering Beneath the Surface: Near Infrared (NIR) Spectroscopy

NIR Spectroscopy might sound like something from a sci-fi movie, but it's straightforward, tested and trusted. This technique uses a type of light that, although invisible to us, can penetrate objects and reveal information about their composition—like moisture and protein levels in grains. Think of it as a superpower that sees beyond the surface, providing a deeper understanding of grain quality.

How Do These Technologies Come Together for Automated Grain Grading

So how does this all come together to provide better grain grading? Let’s show you!

Input: Grain sample is poured into the device.

Analysis: Machine Vision snaps high-resolution images to detect the visual factors in the sample, while the NIR spectrometer scans to assess internal qualities.

Results: Algorithms analyze this data and provide a complete grading result.

The Benefits:

Consistent: By leveraging automated systems, we eliminate the subjectivity typically found in manual grain grading. Each sample is analyzed under the same conditions, delivering repeatable and reliable results every time. This ensures that grading is consistent from sample to sample, providing a standard that you can trust.

Accurate: With the integration of Machine Vision, we conduct a thorough analysis of visual grading factors, capturing up to 25 images per sample for precise evaluations. This detail-oriented approach ensures that every grading factor is considered, enhancing the accuracy of each assessment.

Efficient: Automating the grain grading process significantly cuts down on the time required to assess each sample. By reducing grading time, our system allows you to process samples faster than ever, boosting productivity and enabling more timely decisions in grain handling and marketing.

Comprehensive: Our benchtop unit is equipped to handle grading factors for high throughput bulk grain analysis. From visual factors assessed through Machine Vision to non-visual characteristics measured by NIR Spectroscopy, our system provides a complete insight into each grain sample's quality. This comprehensive analysis ensures that no detail is overlooked, making our system capable of handling the full spectrum of grading requirements.

Changing How We Look at Grain in Our Supply Chain

By adopting these innovative technologies, we’re helping to reshape agricultural practices. Learn more about we do this here.