Decoding Grain Grading

Grain grading can be complex, especially when deciphering factors that impact it. So we sat down with Leigh from our team, to get a better understanding:

1. What does "material grading factor" mean?

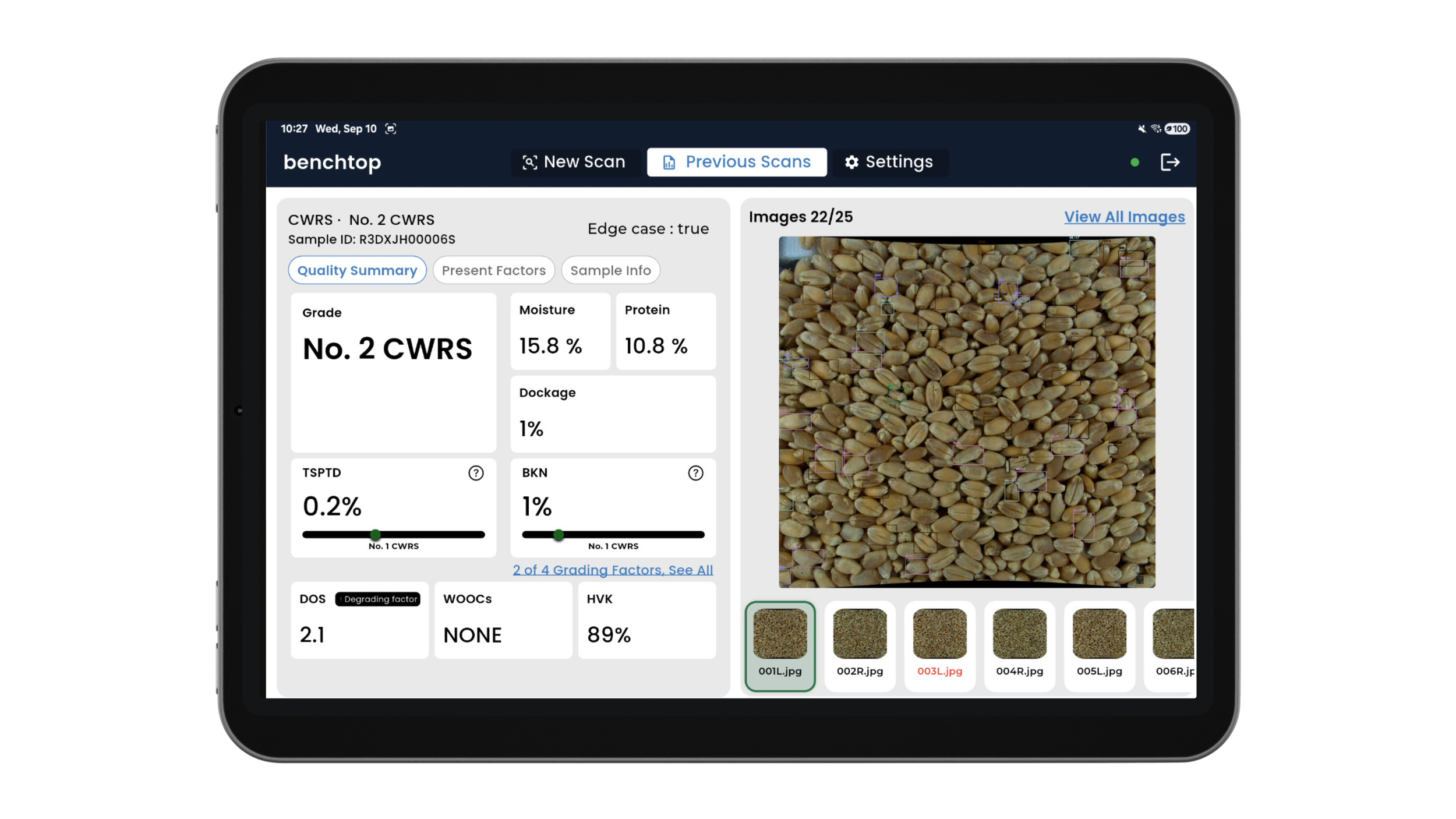

Also known as the degrading factor, these are traits that negatively impact grain quality, determining its grade. Multiple factors may be present, but the most detrimental one is considered the main degrading factor.

2. Why does my grain slip show only a few factors?

Graders focus on elements that could downgrade your grain rather than listing every detail, prioritizing major impact factors.

3. What happens to other components in the sample?

While not always reported back to the farmer, these components may be tracked by handlers for specific end-use contracts, influencing how the grain is utilized beyond the farm.

4. How do rejections and quality checks work?

Quality checks and rejections are based on a variety of factors, primarily focusing on storage conditions and contamination. Proper storage and handling are crucial to prevent issues like spoilage, which can arise from moisture and temperature fluctuations. Graders look for signs of heated, rotted, or moldy grain, which are clear indicators of poor storage.

Additionally, contamination from foreign objects, incorrect crop mixes, or chemicals like seed treatments can lead to rejections. Maintaining clean equipment and storage facilities, monitoring for pests, and ensuring bins are dry and cool can significantly reduce the risk of quality degradation.

Have more questions? Let us know and we’d be happy to answer!