Meet the Factor: Foreign Material

Foreign material is a common grading factor across all crop types and one that often comes into play during harvest and delivery. While it may seem like a minor issue, even small amounts of unwanted material in a sample can affect grade, handling efficiency, and market value.

What is Foreign Material?

Foreign material refers to anything in the sample that is not the grain being graded. It can include pieces of straw, chaff, weed seeds, other grain types, dirt, stones, or insect parts.

Each crop type has different standards for what qualifies as foreign material. For example:

In wheat, barley, and oats, foreign material often comes from straw or other crop residues.

In soybeans, peas, and lentils, it can mean stems, pods, or seeds from other pulse crops.

Why Does Foreign Material Matter?

Foreign material affects grain quality and value in several ways:

Marketability: Buyers and processors expect clean grain. Excess foreign material can result in dockage deductions or rejected loads.

Processing Efficiency: Unwanted material can slow down or damage handling and processing equipment and affect product consistency.

Storage and Safety: Organic material like straw or weed seeds can increase the risk of spoilage, while stones or other debris can pose contamination or safety concerns.

How Does Foreign Material End Up in Grain?

Foreign material is most often introduced during harvest and handling. Common causes include:

Harvest, no matter how well a combine is set, will introduce foreign material into the grain sample, especially in smaller seed types.

Windy or uneven harvest conditions that make clean separation difficult.

Transport and storage systems that are not fully cleaned between crops, causing contamination from previous loads.

What Can Farmers Do?

Farmers can take several steps to minimize foreign material in their grain:

Adjust combine fan speed and sieves for optimal cleaning during harvest.

Clean bins and handling equipment between crops.

Check samples on-farm using automated grading tools to understand foreign material levels before delivery.

What Can Graders Do?

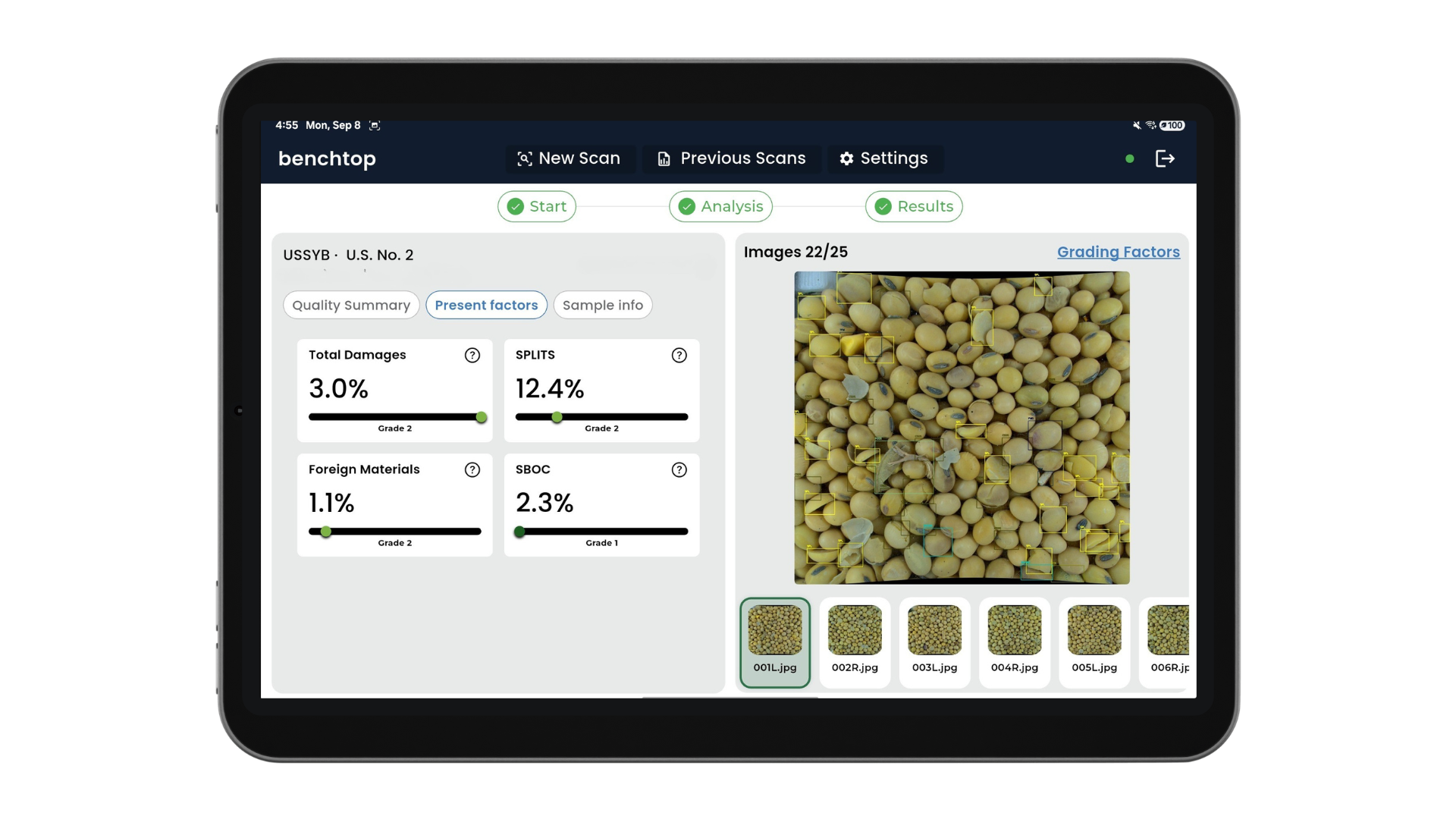

Assessing foreign material can vary from one grader to another, especially when material looks similar to the crop itself. Automated grading helps by:

Providing consistent, objective measurement of foreign material.

Reducing disagreement over dockage and grading results.

Processing samples quickly during busy intake periods.

What Can Processors Do?

Processors rely on clean, uniform grain to maintain quality standards. With accurate grading data, they can:

Segregate lots based on foreign material levels to protect processing quality.

Safeguard equipment and final products from contamination.

Share transparent quality data with suppliers to build confidence across the value chain.

How Ground Truth Ag Can Help

Our automated grading technology provides fast, consistent measurement of foreign material in grain samples. By knowing quality levels immediately, we can all make informed decisions that reduce risk and protect value.